The Truth About the 5 Times RCD Test

- Navitas CP

- Oct 29, 2025

- 3 min read

For years, electricians across the UK have used the 5 times RCD test as part of their on site verification routine. Many were taught that this test was required by BS 7671 and that a device failing the 5 times test was not suitable for installation.

However, the reality is very different.

The 5 times test was never actually a required testing method under BS 7671. It came from the product standards that manufacturers use to validate RCD and RCBO performance under controlled laboratory conditions.

This misunderstanding has shaped testing culture for decades. Now, with the rise of Type A RCDs and the clarification offered in Amendment 2, it is the right time to reset the record, remove confusion, and simplify how we test on site.

Where the 5 Times Test Actually Came From

To understand the confusion, we have to separate two different sets of standards:

⚫️ Product Standards🟢 Wiring Regulations

The product standards for RCDs and RCBOs are:

BS EN 61008 (RCDs)

BS EN 61009 (RCBOs)

These are the standards that ensure devices are designed, built, and tested to operate safely and reliably. The 5 times test lives here, as a performance benchmark.

Under these product standards, a 30 mA device must trip within 40 milliseconds when subjected to 5 × IΔn. This is a manufacturer performance test.

BS 7671 Focuses on Safety, Not Speed

BS 7671 is different. BS 7671 is about installation safety.

For site verification, BS 7671 requires that the RCD or RCBO disconnects within the correct time at 1 × IΔn, which for a 30 mA device is 300 milliseconds for a general non delay device.

This is the test that proves the installation is safe.

If the device trips within the correct time at 1 × IΔn, and the test button operates correctly, the device can be signed off as safe.

The electrician is verifying function, not performance speed.

So Why Did the 5 Times Test Become Common Practice

This is where industry habit meets marketing influence.

Test instrument manufacturers added a 5 times button.Trainers repeated the practice.Brands used 5 times test results to demonstrate performance advantages.

Over time, it became cultural, not regulatory.

When Amendment 2 arrived and removed the reference table (Appendix 3 Table 3A) that showed manufacturer performance data, many assumed the 5 times test had been removed from BS 7671.

But you cannot remove something that was never required in the first place.

Why Type A Devices Changed the Conversation

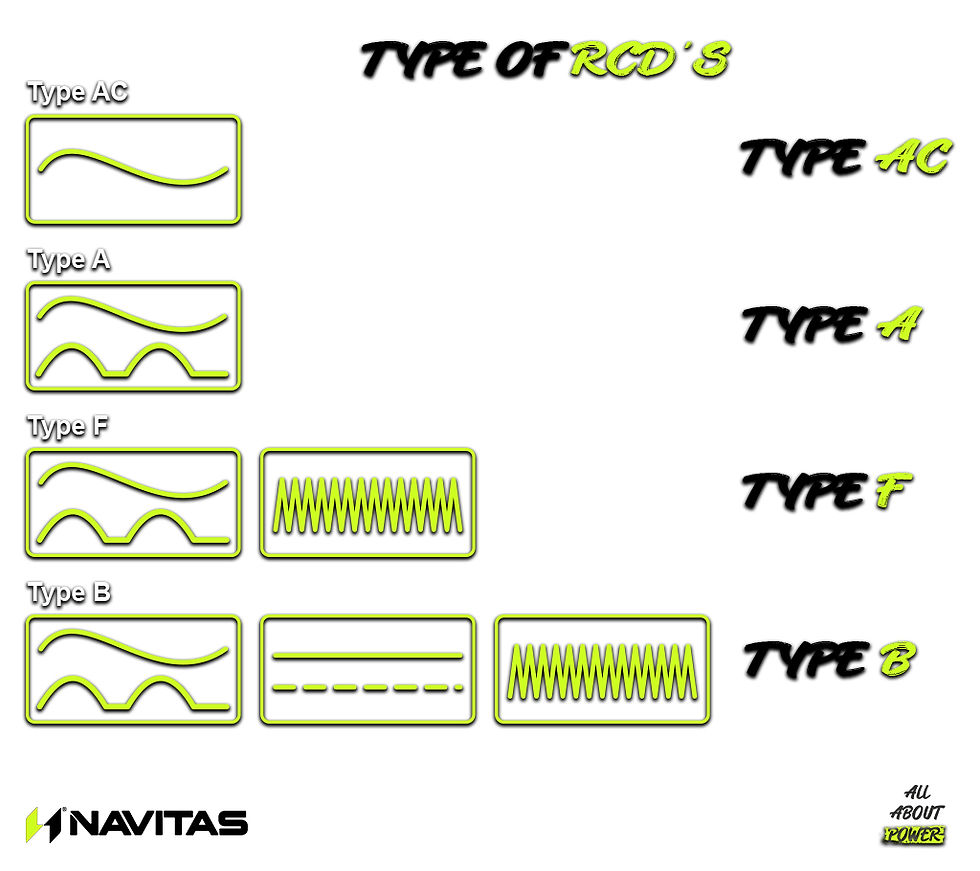

Most installations today use Type A devices rather than Type AC.

Type AC responds to pure AC leakage.

Type A responds to AC and pulsating DC leakage from real world loads like washing machines, chargers, EV points, induction hobs and LED drivers.

Because of this, Type A devices can behave differently under a pure AC 5 times test pulse. A device may appear to trip slightly slower even though it is performing perfectly correctly.

This is one of the main reasons the industry is now moving away from the 5 times test as a universal on site expectation.

What You Should Test On Site

On site, your job is to verify safety and correct operation, not speed.

A safe and compliant test approach:

⚫️ Test using 1 × IΔn

🟢 Confirm the device disconnects within the correct time (≤ 300 ms)

⚫️ Use the test button

🟢 Use the ramp test if you want to see sensitivity or diagnose nuisance tripping

This proves:

The device works

The installation is safe

The protection is real

Why Navitas RCBOs Perform Consistently

At Navitas, every single RCBO is individually tested before it leaves the factory.

Not batch sample testedNot statistically assumedActually tested

This ensures:

Consistent tripping performance

Reliable sensitivity

Stability across real world conditions

The only time that matters is the time when a real fault occurs.That is why we test every device.

Conclusion

The 5 times test was never part of BS 7671. It belongs to the manufacturer product standards.On site, you are proving safety, not laboratory performance.

When you understand the difference between product testing and installation testing, RCD verification becomes simpler, clearer, and far more meaningful.

Comments